-40%

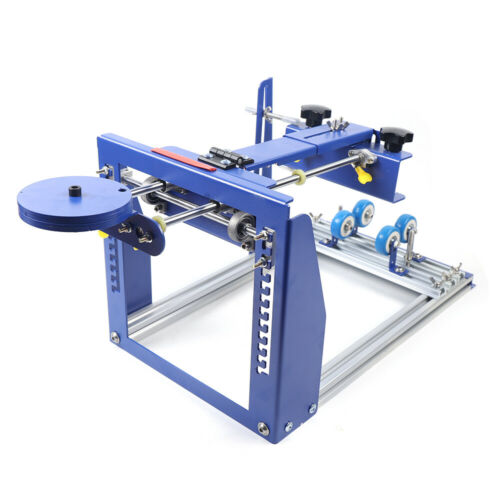

Diameter 19mm Three Sets Metal Bearing Rollers Curved Screen Printing Machine

$ 77.08

- Description

- Size Guide

Description

This machine is mainly used for cylindrical and conical products; such as cylindrical, conical products made of various plastics, glass, metal materials, including wine bottles, medicine bottles, cosmetic bottles and other packaging bottles; mugs , Mugs, beer mugs, wine glasses and other cups; glass tubes, pens, ballpoint pens, fishing rods, bats and other small cylindrical products. For cylindrical and conical products, the printing surface has large depressions or protrusions, and there are non-planar pits in the printing surface, which is not suitable for printing by this machine. This curved screen printing machine is mainly used for printing cylindrical and conical products with a diameter of less than 170 mm.Store category

Sign Up Now !

You may also like

Diameter 19mm Three Sets Metal Bearing Rollers Curved Screen Printing Machine

Product Description

Brand

Unbranded

MPN

Does not apply

Model

QMH170 Type

Printing diameter

under 170mm

mainly used for

cylindrical and conical products

Grade

B Grade

Diameter 19mm Three Sets Metal Bearing Rollers Curved Screen Printing Machine

Caption

This machine is mainly used

for cylindrical and conical products

; such as cylindrical, conical products made of various plastics, glass, metal materials, including

wine bottles

,

medicine bottles

,

cosmetic bottles and other packaging bottles

;

mugs

,

Mugs

,

beer mugs

,

wine glasses and other cups

;

glass tubes

,

pens

,

ballpoint pens

,

fishing rods

,

bats and other small cylindrical products

.

For cylindrical and conical products, the printing surface has large depressions or protrusions, and there are non-planar pits in the printing surface, which is not suitable for printing by this machine.

This curved screen printing machine is mainly used for printing cylindrical and conical products with a

diameter of less than

170 mm

.

1. This machine adopts the front and rear push-pull structure; suitable

for printing width

200 mm

;

length

250 mm

internal pattern; suitable for the use of various screens with an

outer diameter of

280 * 450 mm

and a thickness of less than

40 mm

.

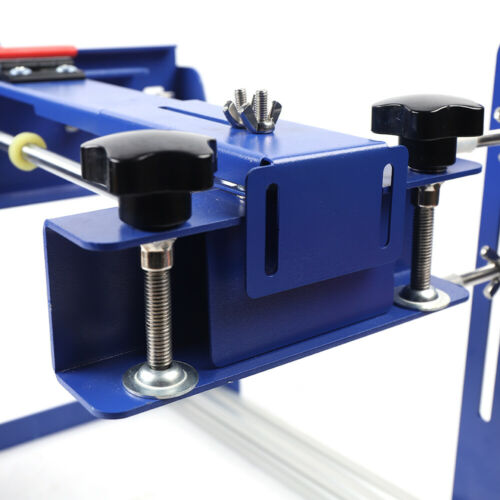

2, the machine adjusts and positions the height of the rear main frame. According to the height of the substrate, the rear main beam is loosened by adjusting the connection screw between the main frame of the screen and the rear (no need to remove the screws), and the whole moves to the long hole Just the right place.

The vertical adjustment range is

160 mm

.

3, the printing frame of the substrate is designed to be movable left and right, and the three fixed aluminum strips at the bottom are directly installed on the two sides of the base. The aluminum strip base can be moved

forward and backward by

300 mm

;

Mounting strip for the substrate positioning bracket. The three mounting bars can be moved left and right as needed.

Installation of aluminum bar displacement: Loosen the two screws of the mounting bar, move to a suitable position, and tighten the two screws to complete the positioning.

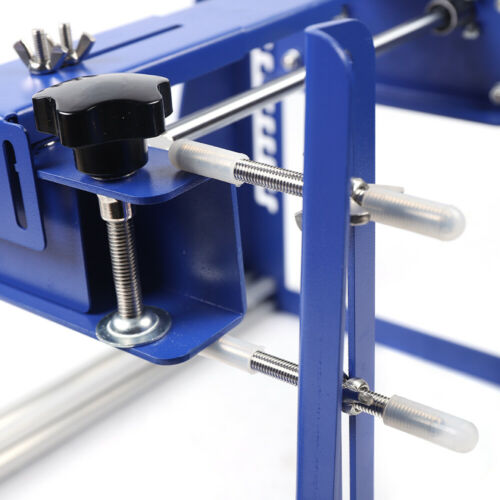

4, three sets of printing materials are used to place the rollers, which are metal

bearing rollers

(diameter 19 mm)

; nylon bearing rollers (diameter plastic bearing rollers

(diameter 50 mm)

, users can replace and use as needed. Both the main frame and the attached frame Install three rollers.

The bearing mounting bracket is directly fixed in the long hole of the aluminum strip installation, and can

move up to

110 mm

left and right according to the width of the substrate; 4 mounting brackets are attached, the bearing on the original main mounting bracket is removed, and the additional mounting bracket is directly fixed on the main with screws On installation, it is mainly used for printing conical products. The additional mounting bracket can be

moved up and down by

20 mm

.

Payment

Delivery details

Terms of sales

About us

Contact us

Payment

We accept ebay payment 。

Fees such as import duties, taxes are not included in the item price or shipping costs. These charges are the buyer's responsibility.

Delivery details

Shipping:

The item will be shipped from our US warehouse to United States, which is more faster than from aboard.

2-9 working days to: USA

Terms of sales

We maintain high standards of excellence and strive for hundred percent customer satisfaction. Feedback is very important to us. We hope that you contact us immediately before you give neutral or negative feedback, so that we can address your concerns. It is impossible to address issues if we do not know about them!

About us

Your satis

faction is our ultimate goal. We work hard to earn your trust and future business. Our certified technicians have tested each item before shipping. The unit comes with 1 year limited warranty on all manufacturing defects.

a) If you receive a defective item, you may return it or ask for a discount. Please contact us within 14 days after you receive the package.

b) What you returned must be intact and in its original packaging as re? u. Customer is responsible for shipping costs of the returned item.

c) We will cover the cost of shipping back t with the shipping rate indicated in the registration page. We will send you a new unit or refund the full payment you paid.

Thank you.

Contact us

Business Hour

Business Hour: Monday To Friday: 8:30 AM to 5:00 PM (Beijing China time)

Due to time zones, our reply to your questions may not be immediately. But within above working time, we will reply your email within 24 hours. If it's non-workdays, please kindly be patient and wait till Monday.

Please contact us with ebay message.

Please feel free to contact us if you have any questions.

: Monday To Friday: 8:30 AM to 5:00 PM (Beijing China time)

Due to time zones, our reply to your questions may not be immediately. But within above working time, we will reply your email within 24 hours. If it's non-workdays, please kindly be patient and wait till Monday.

Please contact us with ebay message.

Please feel free to contact us if you have any questions.

On Jul-01-21 at 20:31:52 PDT, seller added the following information: